| |

Specialists in Timber Frame Design and Construction

| |

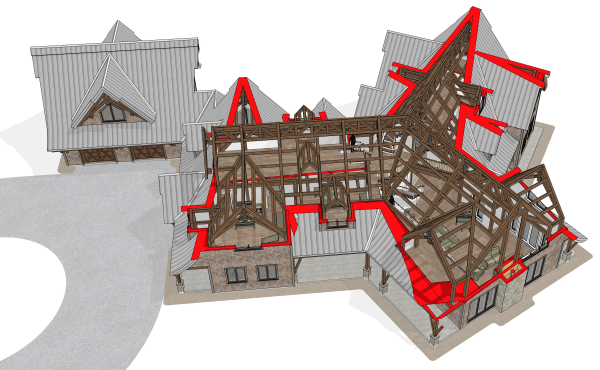

Jackson Hill is a family owned business with over 30 years experience in Timber Frame and Log construction. We specialise in the Design and Manufacture of Timber Frame Buildings and Structures.

We are passionate about Timber Frame and bring that enthusiasm to every project, big or small. We have a practical and down to earth approach, but like to challenge ourselves to create unique and visually stunning structures. We use technology to create spectacular designs in 3D and Traditional Craftsmanship to build them.

For the home owner we offer a complete Custom Timber Frame Design Service and can supply: The Timber Frame only, A Structural Package including the building envelope or A complete Turn Key construction service, in partnership with our approved contractors.

For Professionals, we have the expertise to integrate Timber Frame Elements into any project. We can Design, Engineer, Manufacture and install.

Our goal is always to surpass our customer's expectations and to create homes and structures with timeless character, value and longevity

| |

Our Services

| |

| |

| |

Structural Packages

- Timber Frame

- Sub Floor systems

- Pre-Fabricated Walls

- Roof trusses and more

| |

Turn Key Construction

| |

Who we work for

- Home owners

- Contractors

- Architects

- Designers

- Municipalities

- Developers

| |

| |

PARTNERS

| |